A | B | C | D | E | F | G | H | CH | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9

District heating (also known as heat networks) is a system for distributing heat generated in a centralized location through a system of insulated pipes for residential and commercial heating requirements such as space heating and water heating. The heat is often obtained from a cogeneration plant burning fossil fuels or biomass, but heat-only boiler stations, geothermal heating, heat pumps and central solar heating are also used, as well as heat waste from factories and nuclear power electricity generation. District heating plants can provide higher efficiencies and better pollution control than localized boilers. According to some research, district heating with combined heat and power (CHPDH) is the cheapest method of cutting carbon emissions, and has one of the lowest carbon footprints of all fossil generation plants.[1]

District heating is ranked number 27 in Project Drawdown's 100 solutions to global warming.[2][3]

History

District heating traces its roots to the hot water-heated baths and greenhouses of the ancient Roman Empire. A hot water distribution system in Chaudes-Aigues in France is generally regarded as the first real district heating system. It used geothermal energy to provide heat for about 30 houses and started operation in the 14th century.[4]

The U.S. Naval Academy in Annapolis began steam district heating service in 1853.[citation needed] MIT began coal-fired steam district heating in 1916 when it moved to Cambridge, Massachusetts.[5][6]

Although these and numerous other systems have operated over the centuries, the first commercially successful district heating system was launched in Lockport, New York, in 1877 by American hydraulic engineer Birdsill Holly, considered the founder of modern district heating.

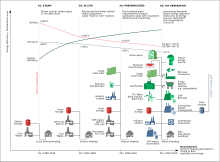

Generations of district heating

Generally, all modern district heating systems are demand driven, meaning that the heat supplier reacts to the demand from the consumers and ensures that there is sufficient temperature and water pressure to deliver the demanded heat to the users. The five generations have defining features that sets them apart from the prior generations. The feature of each generation can be used to give an indication of the development status of an existing district heating system.

First generation

The first generation was a steam-based system fueled by coal and was first introduced in the US in the 1880s and became popular in some European countries, too. It was state of the art until the 1930s. These systems piped very high-temperature steam through concrete ducts, and were therefore not very efficient, reliable, or safe. Nowadays, this generation is technologically outdated. However, some of these systems are still in use, for example in New York or Paris. Other systems originally built have subsequently been upgraded.[7]

Second generation

The second generation was developed in the 1930s and was built until the 1970s. It burned coal and oil, and the energy was transmitted through pressurized hot water as the heat carrier. The systems usually had supply temperatures above 100 °C, and used water pipes in concrete ducts, mostly assembled on site, and heavy equipment. A main reason for these systems was the primary energy savings, which arose from using combined heat and power plants. While also used in other countries, typical systems of this generation were the Soviet-style district heating systems that were built after WW2 in several countries in Eastern Europe.[7]

Third generation

In the 1970s the third generation was developed and was subsequently used in most of the following systems all over the world. This generation is also called the "Scandinavian district heating technology", because many of the district heating component manufacturers are based in Scandinavia. The third generation uses prefabricated, pre-insulated pipes, which are directly buried into the ground and operates with lower temperatures, usually below 100 °C. A primary motivation for building these systems was security of supply by improving the energy efficiency after the two oil crises led to disruption of the oil supply. Therefore, those systems usually used coal, biomass and waste as energy sources, in preference to oil. In some systems, geothermal energy and solar energy are also used in the energy mix.[7] For example, Paris has been using geothermal heating from a 55–70 °C source 1–2 km below the surface for domestic heating since the 1970s.[8]

Fourth generation

Currently,[citation needed] the fourth generation is being developed,[7] with the transition to fourth generation already in process in Denmark.[9] The fourth generation is designed to combat climate change and integrate high shares of variable renewable energy into the district heating by providing high flexibility to the electricity system.[7]

According to the review by Lund et al.[7] those systems have to have the following abilities:

- "Ability to supply low-temperature district heating for space heating and domestic hot water (DHW) to existing buildings, energy-renovated existing buildings and new low-energy buildings."

- "Ability to distribute heat in networks with low grid losses."

- "Ability to recycle heat from low-temperature sources and integrate renewable heat sources such as solar and geothermal heat."

- "Ability to be an integrated part of smart energy systems (i.e. integrated smart electricity, gas, fluid and thermal grids) including being an integrated part of 4th Generation District Cooling systems."

- "Ability to ensure suitable planning, cost and motivation structures in relation to the operation as well as to strategic investments related to the transformation into future sustainable energy systems".

Compared to the previous generations the temperature levels have been reduced to increase the energy efficiency of the system, with supply side temperatures of 70 °C and lower. Potential heat sources are waste heat from industry, CHP plants burning waste, biomass power plants, geothermal and solar thermal energy (central solar heating), large scale heat pumps, waste heat from cooling purposes and data centers and other sustainable energy sources. With those energy sources and large scale thermal energy storage, including seasonal thermal energy storage, fourth generation district heating systems are expected to provide flexibility for balancing wind and solar power generation, for example by using heat pumps to integrate surplus electric power as heat when there is much wind energy or providing electricity from biomass plants when back-up power is needed.[7] Therefore, large scale heat pumps are regarded as a key technology for smart energy systems with high shares of renewable energy up to 100% and advanced fourth generation district heating systems.[10][7][11]

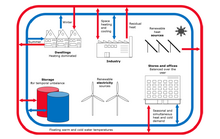

Fifth generation/cold district heating

A fifth generation district heating and cooling network (5GDHC),[12] also called cold district heating, distributes heat at near ambient ground temperature: this in principle minimizes heat losses to the ground and reduces the need for extensive insulation. Each building on the network uses a heat pump in its own plant room to extract heat from the ambient circuit when it needs heat, and uses the same heat pump in reverse to reject heat when it needs cooling. In periods of simultaneous cooling and heating demands this allows waste heat from cooling to be used in heat pumps at those buildings which need heating.[13] The overall temperature within the ambient circuit is preferably controlled by heat exchange with an aquifer or another low temperature water source to remain within a temperature range from 10 °C to 25 °C.

While network piping for ambient ground temperature networks is less expensive to install per pipe diameter than in earlier generations, as it does not need the same degree of insulation for the piping circuits, it has to be kept in mind that the lower temperature difference of the pipe network leads to significantly larger pipe diameters than in prior generations. Due to the requirement of each connected building in the fifth generation district heating and cooling systems to have their own heat pump the system can be used both as a heat source or a heat sink for the heat pump, depending on if it is operated in a heating and cooling mode. As with prior generations the pipe network is an infrastructure that in principle provides an open access for various low temperature heat sources, such as ambient heat, ambient water from rivers, lakes, sea, or lagoons, and waste heat from industrial or commercial sources.[14]

Based on the above description it is clear that there is a fundamental difference between the 5GDHC and the prior generations of district heating, particularly in the individualization of the heat generation. This critical system has a significant impact when comparing the efficiencies between the different generations, as the individualization of the heat generation moves the comparison from being a simple distribution system efficiency comparison to a supply system efficiency comparison, where both the heat generation efficiency as well as the distribution system efficiency needs to be included.

A modern building with a low-temperature internal heat distribution system can install an efficient heat pump delivering heat output at 45 °C. An older building with a higher-temperature internal distribution system e.g. using radiators will require a high-temperature heat pump to deliver heat output.

A larger example of a fifth generation heating and cooling grid is Mijnwater in Heerlen, the Netherlands.[15][16] In this case the distinguishing feature is a unique access to an abandoned water-filled coal mine within the city boundary that provides a stable heat source for the system.

A fifth generation network ("Balanced Energy Network", BEN) was installed in 2016 at two large buildings of the London South Bank University as a research and development project.[17][18]

Heat sources

District heating networks exploit various energy sources, sometimes indirectly through multipurpose infrastructure such as combined heat and power plants (CHP, also called co-generation).

Combustion of fossil or renewable fuels

The most used energy source for district heating is the burning of hydrocarbons. As the supply of renewable fuels is insufficient, the fossil fuels coal and gas are massively used for district heating.[19] This burning of fossil hydrocarbons usually contributes to climate change, as the use of systems to capture and store the CO2 instead of releasing it into the atmosphere is rare.

In the case of a cogeneration plant, the heat output is typically sized to meet half of the peak winter heat load, but over the year will provide 90% of the heat supplied. Much of the heat produced in summer will generally be wasted. The boiler capacity will be able to meet the entire heat demand unaided and can cover for breakdowns in the cogeneration plant. It is not economic to size the cogeneration plant alone to be able to meet the full heat load. In the New York City steam system, that is around 2.5 GW.[20][21] Germany has the largest amount of CHP in Europe.[22]

A simple thermal power station can be 20–35% efficient,[23] whereas a more advanced facility with the ability to recover waste heat can reach total energy efficiency of nearly 80%.[23] Some may approach 100% based on the lower heating value by condensing the flue gas as well.[24]

Nuclear fission

The heat produced by nuclear chain reactions can be injected into district heating networks. This does not contaminate the district pipes with radioactive elements, as the heat is transferred to the network through heat exchangers.[25] It is not technically necessary for the nuclear reactor to be very close to the district heating network, as heat can be transported over significant distances (exceeding 200 km) with affordable losses, using insulated pipes.[26][clarification needed]

Since nuclear reactors do not significantly contribute to either air pollution or global warming, they can be an advantageous alternative to the combustion of fossil hydrocarbons. However, only a small minority of the nuclear reactors currently in operation around the world are connected to a district heating network. These reactors are in Bulgaria, China, Hungary, Romania, Russia, Slovakia, Slovenia, Switzerland and Ukraine.[27]

The Ågesta Nuclear Power Plant in Sweden was an early example of nuclear cogeneration, providing small quantities of both heat and electricity to a suburb of the country's capital between 1964 and 1974. The Beznau Nuclear Power Plant in Switzerland has been generating electricity since 1969 and supplying district heating since 1984. The Haiyang Nuclear Power Plant in China started operating in 2018 and started supplying small scale heat to the Haiyang city area in 2020. By November 2022, the plant used 345 MW-thermal effect to heat 200,000 homes, replacing 12 coal heating plants.[28]

Recent years have seen renewed interest in small modular reactors (SMRs) and their potential to supply district heating.[29] Speaking on the Energy Impact Center's (EIC) podcast, Titans of Nuclear, principal engineer at GE Hitachi Nuclear Energy Christer Dahlgren noted that district heating could be the impetus for the construction of new nuclear power plants in the future.[30] EIC's own open-source SMR blueprint design, OPEN100, could be incorporated into a district heating system.[31]

Natural underground heat

This section needs expansion. You can help by adding to it. (May 2013) |

History

Geothermal district heating was used in Pompeii, and in Chaudes-Aigues since the 14th century.[32]

United States

Direct use geothermal district heating systems, which tap geothermal reservoirs and distribute the hot water to multiple buildings for a variety of uses, are uncommon in the United States, but have existed in America for over a century.

In 1890, the first wells were drilled to access a hot water resource outside of Boise, Idaho. In 1892, after routing the water to homes and businesses in the area via a wooden pipeline, the first geothermal district heating system was created.

As of a 2007 study,[33] there were 22 geothermal district heating systems (GDHS) in the United States. As of 2010, two of those systems have shut down.[34] The table below describes the 20 GDHS currently[when?] operational in America.

| System name | City | State | Startup year |

Number of customers |

Capacity (MWt) |

Annual energy generated (GWh) |

System temperature | |

|---|---|---|---|---|---|---|---|---|

| °F | °C | |||||||

| Warm Springs Water District | Boise | ID | 1892 | 275 | 3.6 | 8.8 | 175 | 79 |

| Oregon Institute of Technology | Klamath Falls | OR | 1964 | 1 | 6.2 | 13.7 | 192 | 89 |

| Midland | Midland | SD | 1969 | 12 | 0.09 | 0.2 | 152 | 67 |

| College of Southern Idaho | Twin Falls | ID | 1980 | 1 | 6.34 | 14 | 100 | 38 |

| Philip | Philip | SD | 1980 | 7 | 2.5 | 5.2 | 151 | 66 |

| Pagosa Springs | Pagosa Springs | CO | 1982 | 22 | 5.1 | 4.8 | 146 | 63 |

| Idaho Capital Mall | Boise | ID | 1982 | 1 | 3.3 | 18.7 | 150 | 66 |

| Elko | Elko | NV | 1982 | 18 | 3.8 | 6.5 | 176 | 80 |

| Boise City | Boise | ID | 1983 | 58 | 31.2 | 19.4 | 170 | 77 |

| Warren Estates | Reno | NV | 1983 | 60 | 1.1 | 2.3 | 204 | 96 |

| San Bernardino | San Bernardino | CA | 1984 | 77 | 12.8 | 22 | 128 | 53 |

| City of Klamath Falls | Klamath Falls | OR | 1984 | 20 | 4.7 | 10.3 | 210 | 99 |

| Manzanita Estates | Reno | NV | 1986 | 102 | 3.6 | 21.2 | 204 | 95 |

| Elko County School District | Elko | NV | 1986 | 4 | 4.3 | 4.6 | 190 | 88 |

| Gila Hot Springs | Glenwood | NM | 1987 | 15 | 0.3 | 0.9 | 140 | 60 |

| Fort Boise Veteran's Hospital Boise | Boise | ID | 1988 | 1 | 1.8 | 3.5 | 161 | 72 |

| Kanaka Rapids Ranch | Buhl | ID | 1989 | 42 | 1.1 | Zdroj:https://en.wikipedia.org?pojem=District_heating|||