A | B | C | D | E | F | G | H | CH | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9

Stained glass is coloured glass as a material or works created from it. Throughout its thousand-year history, the term has been applied almost exclusively to the windows of churches and other significant religious buildings. Although traditionally made in flat panels and used as windows, the creations of modern stained glass artists also include three-dimensional structures and sculpture. Modern vernacular usage has often extended the term "stained glass" to include domestic lead light and objets d'art created from foil glasswork exemplified in the famous lamps of Louis Comfort Tiffany.

As a material stained glass is glass that has been coloured by adding metallic salts during its manufacture, and usually then further decorating it in various ways. The coloured glass is crafted into stained glass windows in which small pieces of glass are arranged to form patterns or pictures, held together (traditionally) by strips of lead, called cames or calms, and supported by a rigid frame. Painted details and yellow stain are often used to enhance the design. The term stained glass is also applied to windows in enamelled glass in which the colours have been painted onto the glass and then fused to the glass in a kiln; very often this technique is only applied to parts of a window.

Stained glass, as an art and a craft, requires the artistic skill to conceive an appropriate and workable design, and the engineering skills to assemble the piece. A window must fit snugly into the space for which it is made, must resist wind and rain, and also, especially in the larger windows, must support its own weight. Many large windows have withstood the test of time and remained substantially intact since the Late Middle Ages. In Western Europe, together with illuminated manuscripts, they constitute the major form of medieval pictorial art to have survived. In this context, the purpose of a stained glass window is not to allow those within a building to see the world outside or even primarily to admit light but rather to control it. For this reason stained glass windows have been described as "illuminated wall decorations".

The design of a window may be abstract or figurative; may incorporate narratives drawn from the Bible, history, or literature; may represent saints or patrons, or use symbolic motifs, in particular armorial. Windows within a building may be thematic, for example: within a church – episodes from the life of Christ; within a parliament building – shields of the constituencies; within a college hall – figures representing the arts and sciences; or within a home – flora, fauna, or landscape.

Glass production

During the late medieval period, glass factories were set up where there was a ready supply of silica, the essential material for glass manufacture. Silica requires a very high temperature to melt, something not all glass factories were able to achieve. Such materials as potash, soda, and lead can be added to lower the melting temperature. Other substances, such as lime, are added to rebuild the weakened network and make the glass more stable. Glass is coloured by adding metallic oxide powders or finely divided metals while it is in a molten state.[1] Copper oxides produce green or bluish green, cobalt makes deep blue, and gold produces wine red and violet glass. Much of modern red glass is produced using copper, which is less expensive than gold and gives a brighter, more vermilion shade of red. Glass coloured while in the clay pot in the furnace is known as pot metal glass, as opposed to flashed glass.

Cylinder or mouth-blown ('muff') glass

Using a blow-pipe, a glass maker will gather a glob of molten glass that was taken from the pot heating in the furnace. The 'gather' is formed to the correct shape and a bubble of air blown into it. Using metal tools, molds of wood that have been soaking in water, and gravity, the gather is manipulated to form a long, cylindrical shape. As it cools, it is reheated so that the manipulation can continue. During the process, the bottom of the cylinder is removed. Once brought to the desired size it is left to cool. One side of the cylinder is opened, and the cylinder is then put into another oven to quickly heat and flatten it, and then placed in an annealer to cool at a controlled rate, making the material more stable. "Hand-blown" or "mouth-blown" cylinder (also called muff glass) and crown glass were the types used in the traditional fabrication of stained-glass windows.

Crown glass

Crown glass is hand-blown glass created by blowing a bubble of air into a gather of molten glass and then spinning it, either by hand or on a table that revolves rapidly like a potter's wheel. The centrifugal force causes the molten bubble to open up and flatten. It can then be cut into small sheets. Glass formed this way can be either coloured and used for stained-glass windows, or uncoloured as seen in small paned windows in 16th- and 17th-century houses. Concentric, curving waves are characteristic of the process. The centre of each piece of glass, known as the "bull's-eye", is subject to less acceleration during spinning, so it remains thicker than the rest of the sheet. It also has the pontil mark, a distinctive lump of glass left by the "pontil" rod, which holds the glass as it is spun out. This lumpy, refractive quality means the bulls-eyes are less transparent, but they have still been used for windows, both domestic and ecclesiastical. Crown glass is still made today, but not on a large scale.

Rolled glass

Rolled glass (sometimes called "table glass") is produced by pouring molten glass onto a metal or graphite table and immediately rolling it into a sheet using a large metal cylinder, similar to rolling out a pie crust. The rolling can be done by hand or by machine. Glass can be "double rolled", which means it is passed through two cylinders at once (similar to the clothes wringers on older washing machines) to yield glass of a specified thickness (typically about 1/8" or 3mm). The glass is then annealed. Rolled glass was first commercially produced around the mid-1830s and is widely used today. It is often called cathedral glass, but this has nothing to do with medieval cathedrals, where the glass used was hand-blown.

Flashed glass

Architectural glass must be at least 1/8 of an inch (3 mm) thick to survive the push and pull of typical wind loads. However, in the creation of red glass, the colouring ingredients must be of a certain concentration, or the colour will not develop. This results in a colour so intense that at the thickness of 1/8 inch (3 mm), the red glass transmits little light and appears black. The method employed to create red stained glass is to laminate a thin layer of red glass to a thicker body of glass that is clear or lightly tinted, forming "flashed glass".

A lightly coloured molten gather is dipped into a pot of molten red glass, which is then blown into a sheet of laminated glass using either the cylinder (muff) or the crown technique described above. Once this method was found for making red glass, other colours were made this way as well. A great advantage is that the double-layered glass can be engraved or abraded to reveal the clear or tinted glass below. The method allows rich detailing and patterns to be achieved without needing to add more lead-lines, giving artists greater freedom in their designs. A number of artists have embraced the possibilities flashed glass gives them. For instance, 16th-century heraldic windows relied heavily on a variety of flashed colours for their intricate crests and creatures. In the medieval period the glass was abraded; later, hydrofluoric acid was used to remove the flash in a chemical reaction (a very dangerous technique), and in the 19th century sandblasting started to be used for this purpose.

Modern production of traditional glass

There are a number of glass factories, notably in Germany, the United States, England, France, Poland and Russia, which produce high-quality glass, both hand-blown (cylinder, muff, crown) and rolled (cathedral and opalescent). Modern stained-glass artists have a number of resources to use and the work of centuries of other artists from which to learn as they continue the tradition in new ways. In the late 19th and 20th centuries there have been many innovations in techniques and in the types of glass used. Many new types of glass have been developed for use in stained glass windows, in particular Tiffany glass and dalle de verre.

Techniques

"Pot metal" and flashed glass

The primary method of including colour in stained glass is to use glass, originally colourless, that has been given colouring by mixing with metal oxides in its melted state (in a crucible or "pot"), producing glass sheets that are coloured all the way through; these are known as "pot metal" glass.[2] A second method, sometimes used in some areas of windows, is flashed glass, a thin coating of coloured glass fused to colourless glass (or coloured glass, to produce a different colour). In medieval glass flashing was especially used for reds, as glass made with gold compounds was very expensive and tended to be too deep in colour to use at full thickness.[3]

Glass paint

Another group of techniques give additional colouring, including lines and shading, by treating the surfaces of the coloured sheets, and often fixing these effects by a light firing in a furnace or kiln. These methods may be used over broad areas, especially with silver stain, which gave better yellows than other methods in the Middle Ages. Alternatively they may be used for painting linear effects, or polychrome areas of detail. The most common method of adding the black linear painting necessary to define stained glass images is the use of what is variously called "glass paint", "vitreous paint", or "grisaille paint". This was applied as a mixture of powdered glass, iron or rust filings to give a black colour, clay, and oil, vinegar or water for a brushable texture, with a binder such as gum arabic. This was painted on the pieces of coloured glass, and then fired to burn away the ingredients giving texture, leaving a layer of the glass and colouring, fused to the main glass piece.[4]

Silver stain

"Silver stain", introduced soon after 1300, produced a wide range of yellow to orange colours; this is the "stain" in the term "stained glass". Silver compounds (notably silver nitrate)[5] are mixed with binding substances, applied to the surface of glass, and then fired in a furnace or kiln.[6] They can produce a range of colours from orange-red to yellow. Used on blue glass they produce greens. The way the glass is heated and cooled can significantly affect the colours produced by these compounds. The chemistry involved is complex and not well understood. The chemicals actually penetrate the glass they are added to a little way, and the technique therefore gives extremely stable results. By the 15th century it had become cheaper than using pot metal glass and was often used with glass paint as the only colour on transparent glass.[7] Silver stain was applied to the opposite face of the glass to silver paint, as the two techniques did not work well one on top of the other. The stain was usually on the exterior face, where it appears to have given the glass some protection against weathering, although this can also be true for paint. They were also probably fired separately, the stain needing a lower heat than the paint.[8]

"Sanguine" or "Cousin's rose"

"Sanguine", "carnation", "Rouge Jean Cousin" or "Cousin's rose", after its supposed inventor,[9] is an iron-based fired paint producing red colours, mainly used to highlight small areas, often on flesh. It was introduced around 1500.[10] Copper stain, similar to silver stain but using copper compounds, also produced reds, and was mainly used in the 18th and 19th centuries.[11]

Cold painting

"Cold paint" is various types of paint that were applied without firing. Contrary to the optimistic claims of the 12th century writer Theophilus Presbyter, cold paint is not very durable, and very little medieval paint has survived.[11]

Scratching techniques

As well as painting, scratched sgraffito techniques were often used. This involved painting a colour over pot metal glass of another colour, and then before firing selectively scratching the glass paint away to make the design, or the lettering of an inscription. This was the most common method of making inscriptions in early medieval glass, giving white or light letters on a black background, with later inscriptions more often using black painted letters on a transparent glass background.[12]

-

Detail from a 13th-century window in the Basilica of Saint-Quentin depicting the creation of a stained-glass window in Middle Ages.

-

Renaissance roundel using only black or brown glass paint, and silver stain. The bishop-saint Lambrecht of Maastricht stands in an extensive landscape, 1510–20. Diameter 8+3⁄4 in (22 cm). Designed to be placed low, close to the viewer.

-

Detail of German panel (1444) of Visitation; pot metal, including white glass, black vitreous paint, yellow silver stain, and olive-green enamel. The plant patterns in the red sky are formed by scratching away black paint from the red glass before firing. Restored with new lead cames.

-

German glass, Nuremberg, after a drawing by Sebald Beham, c. 1525. Silver stain produces a range of yellows and gold, and painted on the reverse of the blue sky, gives the dark green of the cross.[13]

"Pot glass" colours

These are the colours in which the glass itself is made, as opposed to colours applied to the glass.

Transparent glass

Ordinary soda-lime glass appears colourless to the naked eye when it is thin, although iron oxide impurities produce a green tint which becomes evident in thick pieces or with the aid of scientific instruments. A number of additives are used to reduce the green tint, particularly if the glass is to be used for plain window glass, rather than stained glass windows. These additives include manganese dioxide which produces sodium permanganate, and may result in a slightly mauve tint, characteristic of the glass in older houses in New England. Selenium has been used for the same purpose.[14]

Green glass

While very pale green is the typical colour of transparent glass, deeper greens can be achieved by the addition of Iron(II) oxide which results in a bluish-green glass. Together with chromium it gives glass of a richer green colour, typical of the glass used to make wine bottles. The addition of chromium yields dark green glass, suitable for flashed glass.[15] Together with tin oxide[clarification needed] and arsenic it yields emerald green glass.

Blue glass

- In medieval times, blue glass was made by adding cobalt blue, which at a concentration of 0.025% to 0.1% in soda-lime glass achieves the brilliant blue characteristic of Chartres Cathedral.

- The addition of sulphur to boron-rich borosilicate glasses imparts a blue colour.

- The addition of copper oxide at 2–3% produces a turquoise colour.

- The addition of nickel, at different concentrations, produces blue, violet, or black glass.[16]

Red glass

- Metallic gold, in very low concentrations (around 0.001%), produces a rich ruby-coloured glass ("ruby gold"); in even lower concentrations it produces a less intense red, often marketed as "cranberry glass". The colour is caused by the size and dispersion of gold particles. Ruby gold glass is usually made of lead glass with tin added.

- Pure metallic copper produces a very dark red, opaque glass. Glass created in this manner is generally "flashed" (laminated glass). It was used extensively in the late 19th and early 20th centuries and exploited for the decorative effects that could be achieved by sanding and engraving.

- Selenium is an important agent to make pink and red glass. When used together with cadmium sulphide, it yields a brilliant red colour known as "Selenium Ruby".[14]

Yellow glass

- This was very often achieved by "silver stain" applied externally to the sheets of glass (see above).

- The addition of sulphur, together with carbon and iron salts, is used to form iron polysulphides and produce amber glass ranging from yellowish to almost black. With calcium it yields a deep yellow colour.[17]

- Adding titanium produces yellowish-brown glass. Titanium is rarely used on its own and is more often employed to intensify and brighten other additives.

- Cadmium together with sulphur results in deep yellow colour, often used in glazes. However, cadmium is toxic.

- Uranium (0.1% to 2%) can be added to give glass a fluorescent yellow or green colour.[18] Uranium glass is typically not radioactive enough to be dangerous, but if ground into a powder, such as by polishing with sandpaper, and inhaled, it can be carcinogenic. When used with lead glass with a very high proportion of lead, it produces a deep red colour.

Purple glass

- The addition of manganese gives an amethyst colour. Manganese is one of the oldest glass additives, and purple manganese glass has been used since early Egyptian history.

- Nickel, depending on the concentration, produces blue, or violet, or even black glass.[16] Lead crystal with added nickel acquires a purplish colour.

White glass

- Tin dioxide with antimony and arsenic oxides produce an opaque white glass, first used in Venice to produce an imitation porcelain. White glass was used extensively by Louis Comfort Tiffany to create a range of opalescent, mottled and streaky glasses.

-

13th-century window from Chartres showing extensive use of the ubiquitous cobalt blue with green and purple-brown glass, details of amber and borders of flashed red glass.

-

A 19th-century window illustrates the range of colours common in both Medieval and Gothic Revival glass, Lucien Begule, Lyon (1896).

-

A 16th-century window by Arnold of Nijmegen showing the combination of painted glass and intense colour common in Renaissance windows.

-

A late 20th-century window showing a graded range of colours. Ronald Whiting, Chapel Studios. Tattershall Castle, UK.

-

A window by Tiffany illustrating the development and use of multi-coloured flashed, streaky glasses at the end of the 19th century.

Creating stained-glass windows

Designedit

The first stage in the production of a window is to make, or acquire from the architect or owners of the building, an accurate template of the window opening that the glass is to fit.

The subject matter of the window is determined to suit the location, a particular theme, or the wishes of the patron. A small design called a Vidimus (from Latin "we have seen") is prepared which can be shown to the patron. A scaled model maquette may also be provided. The designer must take into account the design, the structure of the window, the nature and size of the glass available and his or her own preferred technique.

A traditional narrative window has panels which relate a story. A figurative window could have rows of saints or dignitaries. Scriptural texts or mottoes are sometimes included and perhaps the names of the patrons or the person to whose memory the window is dedicated. In a window of a traditional type, it is usually left to the discretion of the designer to fill the surrounding areas with borders, floral motifs and canopies.

A full-sized cartoon is drawn for every "light" (opening) of the window. A small church window might typically have two lights, with some simple tracery lights above. A large window might have four or five lights. The east or west window of a large cathedral might have seven lights in three tiers, with elaborate tracery. In medieval times the cartoon was drawn directly on the surface of a whitewashed table, which was then used as a pattern for cutting, painting and assembling the window. The cartoon is then divided into a patchwork, providing a template for each small glass piece. The exact position of the lead which holds the glass in place is also noted, as it is part of the calculated visual effect.

Selecting and painting the glassedit

Each piece of glass is selected for the desired colour and cut to match a section of the template. An exact fit is ensured by "grozing" the edges with a tool which can nibble off small pieces. Details of faces, hair and hands can be painted onto the inner surface of the glass using a special glass paint which contains finely ground lead or copper filings, ground glass, gum arabic and a medium such as wine, vinegar or (traditionally) urine. The art of painting details became increasingly elaborate and reached its height in the early 20th century.

From 1300 onwards, artists started using "silver stain" which was made with silver nitrate. It gave a yellow effect ranging from pale lemon to deep orange. It was usually painted onto the outside of a piece of glass, then fired to make it permanent. This yellow was particularly useful for enhancing borders, canopies and haloes, and turning blue glass into green glass. By about 1450, a stain known as "Cousin's rose" was used to enhance flesh tones.

In the 16th century, a range of glass stains were introduced, most of them coloured by ground glass particles. They were a form of enamelled glass. Painting on glass with these stains was initially used for small heraldic designs and other details. By the 17th century a style of stained glass had evolved that was no longer dependent upon the skilful cutting of coloured glass into sections. Scenes were painted onto glass panels of square format, like tiles. The colours were then annealed to the glass before the pieces were assembled.

A method used for embellishment and gilding is the decoration of one side of each of two pieces of thin glass, which are then placed back to back within the lead came. This allows for the use of techniques such as Angel gilding and Eglomise to produce an effect visible from both sides but not exposing the decorated surface to the atmosphere or mechanical damage.

Assembly and mountingedit

Once the glass is cut and painted, the pieces are assembled by slotting them into H-sectioned lead cames. All the joints are then soldered together and the glass pieces are prevented from rattling and the window made weatherproof by forcing a soft oily cement or mastic between the glass and the cames. In modern windows, copper foil is now sometimes used instead of lead.[19] For further technical details, see Came glasswork.

Traditionally, when a window was inserted into the window space, iron rods were put across it at various points to support its weight. The window was tied to these rods with lead strips or, more recently, with copper wires. Some very large early Gothic windows are divided into sections by heavy metal frames called ferramenta. This method of support was also favoured for large, usually painted, windows of the Baroque period.

- Technical details

-

Maquette by Heaton, Butler and Bayne, 19th-century English manufacturers.

-

Exterior of a window at Sé Velha de Coimbra, Portugal, showing a modern steel armature.

-

Thomas Becket window from Canterbury showing the pot metal and painted glass, lead H-sectioned cames, modern steel rods and copper wire attachments.

-

Skilled glass cutting and leading in a 19th-century window at Meaux Cathedral, France.

Historyedit

Originsedit

Coloured glass has been produced since ancient times. Both the Egyptians and the Romans excelled at the manufacture of small colored glass objects. Phoenicia was important in glass manufacture with its chief centres Sidon, Tyre and Antioch. The British Museum holds two of the finest Roman pieces, the Lycurgus Cup, which is a murky mustard color but glows purple-red to transmitted light, and the cameo glass Portland vase which is midnight blue, with a carved white overlay.

In early Christian churches of the 4th and 5th centuries, there are many remaining windows which are filled with ornate patterns of thinly-sliced alabaster set into wooden frames, giving a stained-glass like effect.[20][21]

Evidence of stained-glass windows in churches and monasteries in Britain can be found as early as the 7th century. The earliest known reference dates from 675 AD when Benedict Biscop imported workmen from France to glaze the windows of the monastery of St Peter which he was building at Monkwearmouth. Hundreds of pieces of coloured glass and lead, dating back to the late 7th century, have been discovered here and at Jarrow.[22][23]

In the Middle East, the glass industry of Syria continued during the Islamic period with major centres of manufacture at Raqqa, Aleppo and Damascus and the most important products being highly transparent colourless glass and gilded glass, rather than coloured glass.[24][25]

-

A perfume flask from 100 BC to 200 AD

-

The Portland Vase, a rare example of Roman flashed glass

In Southwest Asiaedit

The creation of stained glass in Southwest Asia began in ancient times. One of the region's earliest surviving formulations for the production of colored glass comes from the Assyrian city of Nineveh, dating to the 7th-century BC. The Kitab al-Durra al-Maknuna, attributed to the 8th century alchemist Jābir ibn Hayyān, discusses the production of colored glass in ancient Babylon and Egypt. The Kitab al-Durra al-Maknuna also describes how to create colored glass and artificial gemstones made from high-quality stained glass.[26] The tradition of stained glass manufacture has continued, with mosques, palaces, and public spaces being decorated with stained glass throughout the Islamic world. The stained glass of Islam is generally non-pictorial and of purely geometric design, but may contain both floral motifs and text.

Stained glass creation had flourished in Persia (now Iran) during the Safavid dynasty (1501–1736 A.D.), and Zand dynasty (1751–1794 A.D.).[27] In Persia stained glass sash windows are called Orosi windows (or transliterated as Arasi, and Orsi), and were once used for decoration, as well as controlling the incoming sunlight in the hot and semi-arid climate.[27][28]

-

Extensive stained glasses of Nasir-ol-Molk Mosque in Shiraz, Iran and the light passing through them

-

From a mosque in Jerusalem, this window contains highly detailed text.

Medieval glass in Europeedit

Stained glass, as an art form, reached its height in the Middle Ages when it became a major pictorial form used to illustrate the narratives of the Bible to a largely illiterate populace.

In the Romanesque and Early Gothic period, from about 950 to 1240, the untraceried windows demanded large expanses of glass which of necessity were supported by robust iron frames, such as may be seen at Chartres Cathedral and at the eastern end of Canterbury Cathedral. As Gothic architecture developed into a more ornate form, windows grew larger, affording greater illumination to the interiors, but were divided into sections by vertical shafts and tracery of stone. This elaboration of form reached its height of complexity in the Flamboyant style in Europe, and windows grew still larger with the development of the Perpendicular style in England and Rayonnant style in France.

Integrated with the lofty verticals of Gothic cathedrals and parish churches, glass designs became more daring. The circular form, or rose window, developed in France from relatively simple windows with openings pierced through slabs of thin stone to wheel windows, as exemplified by the west front of Chartres Cathedral, and ultimately to designs of enormous complexity, the tracery being drafted from hundreds of different points, such as those at Sainte-Chapelle, Paris and the "Bishop's Eye" at Lincoln Cathedral.

While stained glass was widely manufactured, Chartres was the greatest centre of stained glass manufacture, producing glass of unrivalled quality.[29]

- Medieval glass in France

-

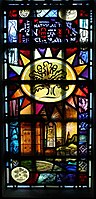

Detail of a 13th-century window from Chartres Cathedral

-

Charlemagne from a Romanesque window in Strasbourg Cathedral

-

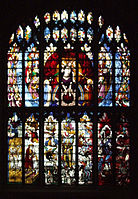

The Crucifixion window of Poitiers Cathedral

-

Late Gothic Tree of Jesse window from Evreux Cathedral

-

The south transept windows from Chartres Cathedral

- Medieval glass in Germany and Austria

-

King David from Augsburg Cathedral, early 12th century. One of the oldest examples in situ.

-

Crucifixion with Ss Catherine, George and Margaret, Leechkirche, Graz, Austria

-

The Crucifixion and Virgin and Child in Majesty, Cologne Cathedral, (1340)

-

Ulm Munster, The Last Judgement by Hans Acker (1430)

-

The windows of the choir of Cologne Cathedral, (early 14th century)

- Medieval glass in England

-

Detail of a Tree of Jesse from York Minster (c. 1170), the oldest stained-glass window in England.

-

The Poor Man's Bible Window from Canterbury Cathedral

-

South transept window at Canterbury Cathedral, 13th century

-

The west window of York Minster (1338–39)

Renaissance, Reformation and Classical windowsedit

Probably the earliest scheme of stained glass windows that was created during the Renaissance was that for Florence Cathedral, devised by Lorenzo Ghiberti.[31] The scheme includes three ocular windows for the dome and three for the facade which were designed from 1405 to 1445 by several of the most renowned artists of this period: Ghiberti, Donatello, Uccello and Andrea del Castagno. Each major ocular window contains a single picture drawn from the Life of Christ or the Life of the Virgin Mary, surrounded by a wide floral border, with two smaller facade windows by Ghiberti showing the martyred deacons, St Stephen and St Lawrence. One of the cupola windows has since been lost, and that by Donatello has lost nearly all of its painted details.[31]

In Europe, stained glass continued to be produced; the style evolved from the Gothic to the Classical, which is well represented in Germany, Belgium and the Netherlands, despite the rise of Protestantism. In France, much glass of this period was produced at the Limoges factory, and in Italy at Murano, where stained glass and faceted lead crystal are often coupled together in the same window. The French Revolution brought about the neglect or destruction of many windows in France. Nonetheless, the country still holds the largest set of Renaissance stained glass in its churches, particularly in the regions of Normandy and Champagne where there were vivid ateliers in many cities until the early 17th century with the stained glass painter Linard Gonthier being active in Troyes until 1642. There are 1042 preserved 16th-century windows in the Aube department alone[32].

At the Reformation in England, large numbers of medieval and Renaissance windows were smashed and replaced with plain glass. The Dissolution of the Monasteries under Henry VIII and the injunctions of Thomas Cromwell against "abused images" (the object of veneration) resulted in the loss of thousands of windows. Few remain undamaged; of these the windows in the private chapel at Hengrave Hall in Suffolk are among the finest. With the latter wave of destruction the traditional methods of working with stained glass died, and were not rediscovered in England until the early 19th century. See Stained glass – British glass, 1811–1918 for more details.

In the Netherlands a rare scheme of glass has remained intact at Grote Sint-Jan Church, Gouda. The windows, some of which are 18 metres (59 feet) high, date from 1555 to the early 1600s; the earliest is the work of Dirck Crabeth and his brother Wouter. Many of the original cartoons still exist.[33]

-

The Resurrection, Paolo Uccello (1443–45), one of a series in the dome of Florence Cathedral designed by renowned Renaissance artists.

-

Giovanni di Domenico, The Angel of the Annunciation, 1498–1503, National Gallery of Art.

-

Stained glass from Seville Cathedral, Enrique Alemán, 1479

-

Auch Cathedral (France), Renaissance stained glass by Arnaud de Moles (detail), 1507–1513).

-

Tree of Jesse window, Church of St-Étienne, Beauvais, France, Engrand Le Prince (1522–1524).

-

Detail of Adam and Eve from the Cathedral of St-Etienne, Châlons-en-Champagne, France.

-

Renaissance window in the church of SS Giovanni and Paolo, Venice 16th century.

-

Window of the Conversion of St Paol, Chapel od St James, Seville Cathedral, Spain, Visente Mentdo, 1560

-

The Triumph of Freedom of Conscience, Sint Janskerk, maker Adriaen Gerritszoon de Vrije (Gouda); design Joachim Wtewael (Utrecht) (1595–1600).

-

Domestic window by Dirck Crabeth for the house of Adriaen Dircxzoon van Crimpen of Leiden (1543). The windows show scenes from the lives of the Prophet Samuel and the Apostle Paul. Musée des Arts Décoratifs, Paris.[33]

-

The Passion of Christ: the Capture and Crucifixion, Saint-Pierre, Limours, Essonne, France (1520).

-

Glass painting depicting Mordnacht (murder night) on 23/24 February 1350 and heraldry of the first Meisen guild's Zunfthaus, Zürich (c. 1650).

-

The story of how the Crown of Thorns passed from John of Brienne and Baldwin II of Constantinople to Saint Louis IX of France, Moulins Cathedral (16th century).

-

The Death and Assumption of the Virgin Mary, Church of SS Ägidius and Koloman, Steyr, Austria.

In Latin Americaedit

Stained glass was first imported to Latin America during the 17th-18th century by Portuguese and Spanish settlers.By the 20th century many European artists had begun to establish their own studios within Latin America and had started up local production. With these new local studios came inventive techniques and less traditional imagery.[34] Examples of these more modern works of art are the Basílica Nuestra Señora de Lourde and the Templo Vótivo de Maipú both located in Chile.

-

Largest rose window in the Basílica del Voto Nacional located in Quito, Ecuador

-

Large stained glass window at the Basílica Nuestra Señora de Lourdes. Located in Buenos Aires, Argentina

Zdroj:https://en.wikipedia.org?pojem=Stained_glass_window

Text je dostupný za podmienok Creative Commons Attribution/Share-Alike License 3.0 Unported; prípadne za ďalších podmienok. Podrobnejšie informácie nájdete na stránke Podmienky použitia.

Antropológia

Aplikované vedy

Bibliometria

Dejiny vedy

Encyklopédie

Filozofia vedy

Forenzné vedy

Humanitné vedy

Knižničná veda

Kryogenika

Kryptológia

Kulturológia

Literárna veda

Medzidisciplinárne oblasti

Metódy kvantitatívnej analýzy

Metavedy

Metodika

Text je dostupný za podmienok Creative

Commons Attribution/Share-Alike License 3.0 Unported; prípadne za ďalších

podmienok.

Podrobnejšie informácie nájdete na stránke Podmienky

použitia.

www.astronomia.sk | www.biologia.sk | www.botanika.sk | www.dejiny.sk | www.economy.sk | www.elektrotechnika.sk | www.estetika.sk | www.farmakologia.sk | www.filozofia.sk | Fyzika | www.futurologia.sk | www.genetika.sk | www.chemia.sk | www.lingvistika.sk | www.politologia.sk | www.psychologia.sk | www.sexuologia.sk | www.sociologia.sk | www.veda.sk I www.zoologia.sk