A | B | C | D | E | F | G | H | CH | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9

| Computer memory and Computer data storage types |

|---|

| Volatile |

| Non-volatile |

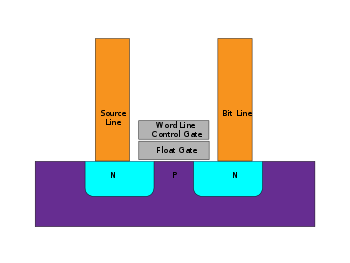

Flash memory is an electronic non-volatile computer memory storage medium that can be electrically erased and reprogrammed. The two main types of flash memory, NOR flash and NAND flash, are named for the NOR and NAND logic gates. Both use the same cell design, consisting of floating gate MOSFETs. They differ at the circuit level depending on whether the state of the bit line or word lines is pulled high or low: in NAND flash, the relationship between the bit line and the word lines resembles a NAND gate; in NOR flash, it resembles a NOR gate.

Flash memory, a type of floating-gate memory, was invented at Toshiba in 1980 and is based on EEPROM technology. Toshiba began marketing flash memory in 1987.[1] EPROMs had to be erased completely before they could be rewritten. NAND flash memory, however, may be erased, written, and read in blocks (or pages), which generally are much smaller than the entire device. NOR flash memory allows a single machine word to be written – to an erased location – or read independently. A flash memory device typically consists of one or more flash memory chips (each holding many flash memory cells), along with a separate flash memory controller chip.

The NAND type is found mainly in memory cards, USB flash drives, solid-state drives (those produced since 2009), feature phones, smartphones, and similar products, for general storage and transfer of data. NAND or NOR flash memory is also often used to store configuration data in digital products, a task previously made possible by EEPROM or battery-powered static RAM. A key disadvantage of flash memory is that it can endure only a relatively small number of write cycles in a specific block.[2]

NOR Flash is known for its direct random access capabilities, making it apt for executing code directly. Its architecture allows for individual byte access, facilitating faster read speeds compared to NAND Flash. NAND Flash memory operates with a different architecture, relying on a serial access approach. This makes NAND suitable for high-density data storage but less efficient for random access tasks. NAND Flash is often employed in scenarios where cost-effective, high-capacity storage is crucial, such as in USB drives, memory cards, and solid-state drives (SSDs).

The primary differentiator lies in their use cases and internal structures. NOR Flash is optimal for applications requiring quick access to individual bytes, like in embedded systems for program execution. NAND Flash, on the other hand, shines in scenarios demanding cost-effective, high-capacity storage with sequential data access.

Flash memory[3] is used in computers, PDAs, digital audio players, digital cameras, mobile phones, synthesizers, video games, scientific instrumentation, industrial robotics, and medical electronics. Flash memory has a fast read access time but it is not as fast as static RAM or ROM. In portable devices, it is preferred to use flash memory because of its mechanical shock resistance since mechanical drives are more prone to mechanical damage.[4]

Because erase cycles are slow, the large block sizes used in flash memory erasing give it a significant speed advantage over non-flash EEPROM when writing large amounts of data. As of 2019,[update] flash memory costs greatly less than byte-programmable EEPROM and had become the dominant memory type wherever a system required a significant amount of non-volatile solid-state storage. EEPROMs, however, are still used in applications that require only small amounts of storage, as in serial presence detect.[5][6]

Flash memory packages can use die stacking with through-silicon vias and several dozen layers of 3D TLC NAND cells (per die) simultaneously to achieve capacities of up to 1 tebibyte per package using 16 stacked dies and an integrated flash controller as a separate die inside the package.[7][8][9][10]

History

Background

The origins of flash memory can be traced back to the development of the floating-gate MOSFET (FGMOS), also known as the floating-gate transistor.[11][12] The original MOSFET (metal–oxide–semiconductor field-effect transistor), also known as the MOS transistor, was invented by Egyptian engineer Mohamed M. Atalla and Korean engineer Dawon Kahng at Bell Labs in 1959.[13] Kahng went on to develop a variation, the floating-gate MOSFET, with Taiwanese-American engineer Simon Min Sze at Bell Labs in 1967.[14] They proposed that it could be used as floating-gate memory cells for storing a form of programmable read-only memory (PROM) that is both non-volatile and re-programmable.[14]

Early types of floating-gate memory included EPROM (erasable PROM) and EEPROM (electrically erasable PROM) in the 1970s.[14] However, early floating-gate memory required engineers to build a memory cell for each bit of data, which proved to be cumbersome,[15] slow,[16] and expensive, restricting floating-gate memory to niche applications in the 1970s, such as military equipment and the earliest experimental mobile phones.[11]

Invention and commercialization

Fujio Masuoka, while working for Toshiba, proposed a new type of floating-gate memory that allowed entire sections of memory to be erased quickly and easily, by applying a voltage to a single wire connected to a group of cells.[11] This led to Masuoka's invention of flash memory at Toshiba in 1980.[15][17][18] According to Toshiba, the name "flash" was suggested by Masuoka's colleague, Shōji Ariizumi, because the erasure process of the memory contents reminded him of the flash of a camera.[19] Masuoka and colleagues presented the invention of NOR flash in 1984,[20][21] and then NAND flash at the IEEE 1987 International Electron Devices Meeting (IEDM) held in San Francisco.[22]

Toshiba commercially launched NAND flash memory in 1987.[1][14] Intel Corporation introduced the first commercial NOR type flash chip in 1988.[23] NOR-based flash has long erase and write times, but provides full address and data buses, allowing random access to any memory location. This makes it a suitable replacement for older read-only memory (ROM) chips, which are used to store program code that rarely needs to be updated, such as a computer's BIOS or the firmware of set-top boxes. Its endurance may be from as little as 100 erase cycles for an on-chip flash memory,[24] to a more typical 10,000 or 100,000 erase cycles, up to 1,000,000 erase cycles.[25] NOR-based flash was the basis of early flash-based removable media; CompactFlash was originally based on it, though later cards moved to less expensive NAND flash.

NAND flash has reduced erase and write times, and requires less chip area per cell, thus allowing greater storage density and lower cost per bit than NOR flash. However, the I/O interface of NAND flash does not provide a random-access external address bus. Rather, data must be read on a block-wise basis, with typical block sizes of hundreds to thousands of bits. This makes NAND flash unsuitable as a drop-in replacement for program ROM, since most microprocessors and microcontrollers require byte-level random access. In this regard, NAND flash is similar to other secondary data storage devices, such as hard disks and optical media, and is thus highly suitable for use in mass-storage devices, such as memory cards and solid-state drives (SSD). For example, SSDs store data using multiple NAND flash memory chips.

The first NAND-based removable memory card format was SmartMedia, released in 1995. Many others followed, including MultiMediaCard, Secure Digital, Memory Stick, and xD-Picture Card.

Later developments

A new generation of memory card formats, including RS-MMC, miniSD and microSD, feature extremely small form factors. For example, the microSD card has an area of just over 1.5 cm2, with a thickness of less than 1 mm.

NAND flash has achieved significant levels of memory density as a result of several major technologies that were commercialized during the late 2000s to early 2010s.[26]

NOR flash was the most common type of Flash memory sold until 2005, when NAND flash overtook NOR flash in sales.[27]

Multi-level cell (MLC) technology stores more than one bit in each memory cell. NEC demonstrated multi-level cell (MLC) technology in 1998, with an 80 Mb flash memory chip storing 2 bits per cell.[28] STMicroelectronics also demonstrated MLC in 2000, with a 64 MB NOR flash memory chip.[29] In 2009, Toshiba and SanDisk introduced NAND flash chips with QLC technology storing 4 bits per cell and holding a capacity of 64 Gbit.[30][31] Samsung Electronics introduced triple-level cell (TLC) technology storing 3-bits per cell, and began mass-producing NAND chips with TLC technology in 2010.[32]

Charge trap flash

Charge trap flash (CTF) technology replaces the polysilicon floating gate, which is sandwiched between a blocking gate oxide above and a tunneling oxide below it, with an electrically insulating silicon nitride layer; the silicon nitride layer traps electrons. In theory, CTF is less prone to electron leakage, providing improved data retention.[33][34][35][36][37][38]

Because CTF replaces the polysilicon with an electrically insulating nitride, it allows for smaller cells and higher endurance (lower degradation or wear). However, electrons can become trapped and accumulate in the nitride, leading to degradation. Leakage is exacerbated at high temperatures since electrons become more excited with increasing temperatures. CTF technology however still uses a tunneling oxide and blocking layer which are the weak points of the technology, since they can still be damaged in the usual ways (the tunnel oxide can be degraded due to extremely high electric fields and the blocking layer due to Anode Hot Hole Injection (AHHI).[39][40]

Degradation or wear of the oxides is the reason why flash memory has limited endurance, and data retention goes down (the potential for data loss increases) with increasing degradation, since the oxides lose their electrically insulating characteristics as they degrade. The oxides must insulate against electrons to prevent them from leaking which would cause data loss.

In 1991, NEC researchers including N. Kodama, K. Oyama and Hiroki Shirai described a type of flash memory with a charge trap method.[41] In 1998, Boaz Eitan of Saifun Semiconductors (later acquired by Spansion) patented a flash memory technology named NROM that took advantage of a charge trapping layer to replace the conventional floating gate used in conventional flash memory designs.[42] In 2000, an Advanced Micro Devices (AMD) research team led by Richard M. Fastow, Egyptian engineer Khaled Z. Ahmed and Jordanian engineer Sameer Haddad (who later joined Spansion) demonstrated a charge-trapping mechanism for NOR flash memory cells.[43] CTF was later commercialized by AMD and Fujitsu in 2002.[44] 3D V-NAND (vertical NAND) technology stacks NAND flash memory cells vertically within a chip using 3D charge trap flash (CTP) technology. 3D V-NAND technology was first announced by Toshiba in 2007,[45] and the first device, with 24 layers, was first commercialized by Samsung Electronics in 2013.[46][47]

3D integrated circuit technology

3D integrated circuit (3D IC) technology stacks integrated circuit (IC) chips vertically into a single 3D IC chip package.[26] Toshiba introduced 3D IC technology to NAND flash memory in April 2007, when they debuted a 16 GB eMMC compliant (product number THGAM0G7D8DBAI6, often abbreviated THGAM on consumer websites) embedded NAND flash memory chip, which was manufactured with eight stacked 2 GB NAND flash chips.[48] In September 2007, Hynix Semiconductor (now SK Hynix) introduced 24-layer 3D IC technology, with a 16 GB flash memory chip that was manufactured with 24 stacked NAND flash chips using a wafer bonding process.[49] Toshiba also used an eight-layer 3D IC for their 32 GB THGBM flash chip in 2008.[50] In 2010, Toshiba used a 16-layer 3D IC for their 128 GB THGBM2 flash chip, which was manufactured with 16 stacked 8 GB chips.[51] In the 2010s, 3D ICs came into widespread commercial use for NAND flash memory in mobile devices.[26]

In 2016, Micron and Intel introduced a technology known as CMOS Under the Array/CMOS Under Array (CUA), Core over Periphery (COP), Periphery Under Cell (PUA), or Xtacking,[52] in which the control circuitry for the flash memory is placed under or above the flash memory cell array. This has allowed for an increase in the number of planes or sections a flash memory chip has, increasing from 2 planes to 4, without increasing the area dedicated to the control or periphery circuitry. This increases the number of IO operations per flash chip or die, but it also introduces challenges when building capacitors for charge pumps used to write to the flash memory.[53][54][55] Some flash dies have as many as 8 planes.[56]

As of August 2017, microSD cards with a capacity up to 400 GB (400 billion bytes) are available.[57][58] The same year, Samsung combined 3D IC chip stacking with its 3D V-NAND and TLC technologies to manufacture its 512 GB KLUFG8R1EM flash memory chip with eight stacked 64-layer V-NAND chips.[8] In 2019, Samsung produced a 1024 GB flash chip, with eight stacked 96-layer V-NAND chips and with QLC technology.[59][60]

Principles of operation

Flash memory stores information in an array of memory cells made from floating-gate transistors. In single-level cell (SLC) devices, each cell stores only one bit of information. Multi-level cell (MLC) devices, including triple-level cell (TLC) devices, can store more than one bit per cell.

The floating gate may be conductive (typically polysilicon in most kinds of flash memory) or non-conductive (as in SONOS flash memory).[61]

Floating-gate MOSFET

In flash memory, each memory cell resembles a standard metal–oxide–semiconductor field-effect transistor (MOSFET) except that the transistor has two gates instead of one. The cells can be seen as an electrical switch in which current flows between two terminals (source and drain) and is controlled by a floating gate (FG) and a control gate (CG). The CG is similar to the gate in other MOS transistors, but below this, there is the FG insulated all around by an oxide layer. The FG is interposed between the CG and the MOSFET channel. Because the FG is electrically isolated by its insulating layer, electrons placed on it are trapped. When the FG is charged with electrons, this charge screens the electric field from the CG, thus, increasing the threshold voltage (VT) of the cell. This means that the VT of the cell can be changed between the uncharged FG threshold voltage (VT1) and the higher charged FG threshold voltage (VT2) by changing the FG charge. In order to read a value from the cell, an intermediate voltage (VI) between VT1 and VT2 is applied to the CG. If the channel conducts at VI, the FG must be uncharged (if it were charged, there would not be conduction because VI is less than VT2). If the channel does not conduct at the VI, it indicates that the FG is charged. The binary value of the cell is sensed by determining whether there is current flowing through the transistor when VI is asserted on the CG. In a multi-level cell device, which stores more than one bit per cell, the amount of current flow is sensed (rather than simply its presence or absence), in order to determine more precisely the level of charge on the FG.

Floating gate MOSFETs are so named because there is an electrically insulating tunnel oxide layer between the floating gate and the silicon, so the gate "floats" above the silicon. The oxide keeps the electrons confined to the floating gate. Degradation or wear (and the limited endurance of floating gate Flash memory) occurs due to the extremely high electric field (10 million volts per centimeter) experienced by the oxide. Such high voltage densities can break atomic bonds over time in the relatively thin oxide, gradually degrading its electrically insulating properties and allowing electrons to be trapped in and pass through freely (leak) from the floating gate into the oxide, increasing the likelihood of data loss since the electrons (the quantity of which is used to represent different charge levels, each assigned to a different combination of bits in MLC Flash) are normally in the floating gate. This is why data retention goes down and the risk of data loss increases with increasing degradation.[62][63][37][64][65] The silicon oxide in a cell degrades with every erase operation. The degradation increases the amount of negative charge in the cell over time due to trapped electrons in the oxide and negates some of the control gate voltage, this over time also makes erasing the cell slower, so to maintain the performance and reliability of the NAND chip, the cell must be retired from use. Endurance also decreases with the number of bits in a cell. With more bits in a cell, the number of possible states (each represented by a different voltage level) in a cell increases and is more sensitive to the voltages used for programming. Voltages may be adjusted to compensate for degradation of the silicon oxide, and as the number of bits increases, the number of possible states also increases and thus the cell is less tolerant of adjustments to programming voltages, because there is less space between the voltage levels that define each state in a cell.[66]

Zdroj:https://en.wikipedia.org?pojem=Flash_memoryText je dostupný za podmienok Creative Commons Attribution/Share-Alike License 3.0 Unported; prípadne za ďalších podmienok. Podrobnejšie informácie nájdete na stránke Podmienky použitia.

Antropológia

Aplikované vedy

Bibliometria

Dejiny vedy

Encyklopédie

Filozofia vedy

Forenzné vedy

Humanitné vedy

Knižničná veda

Kryogenika

Kryptológia

Kulturológia

Literárna veda

Medzidisciplinárne oblasti

Metódy kvantitatívnej analýzy

Metavedy

Metodika

Text je dostupný za podmienok Creative

Commons Attribution/Share-Alike License 3.0 Unported; prípadne za ďalších

podmienok.

Podrobnejšie informácie nájdete na stránke Podmienky

použitia.

www.astronomia.sk | www.biologia.sk | www.botanika.sk | www.dejiny.sk | www.economy.sk | www.elektrotechnika.sk | www.estetika.sk | www.farmakologia.sk | www.filozofia.sk | Fyzika | www.futurologia.sk | www.genetika.sk | www.chemia.sk | www.lingvistika.sk | www.politologia.sk | www.psychologia.sk | www.sexuologia.sk | www.sociologia.sk | www.veda.sk I www.zoologia.sk