A | B | C | D | E | F | G | H | CH | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9

Centrifugal compressors, sometimes called impeller compressors or radial compressors, are a sub-class of dynamic axisymmetric work-absorbing turbomachinery.[1]

They achieve pressure rise by adding energy to the continuous flow of fluid through the rotor/impeller. The equation in the next section shows this specific energy input. A substantial portion of this energy is kinetic which is converted to increased potential energy/static pressure by slowing the flow through a diffuser. The static pressure rise in the impeller may roughly equal the rise in the diffuser.

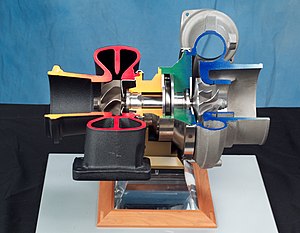

Components of a simple centrifugal compressor

A simple centrifugal compressor stage has four components (listed in order of throughflow): inlet, impeller/rotor, diffuser, and collector.[1] Figure 1.1 shows each of the components of the flow path, with the flow (working gas) entering the centrifugal impeller axially from left to right. This turboshaft (or turboprop) impeller is rotating counter-clockwise when looking downstream into the compressor. The flow will pass through the compressors from left to right.

Inlet

The simplest inlet to a centrifugal compressor is typically a simple pipe. Depending upon its use/application inlets can be very complex. They may include other components such as an inlet throttle valve, a shrouded port, an annular duct (see Figure 1.1), a bifurcated duct, stationary guide vanes/airfoils used to straight or swirl flow (see Figure 1.1), movable guide vanes (used to vary pre-swirl adjustably). Compressor inlets often include instrumentation to measure pressure and temperature in order to control compressor performance.

Bernoulli's fluid dynamic principle plays an important role in understanding vaneless stationary components like an inlet. In engineering situations assuming adiabatic flow, this equation can be written in the form:

Equation-1.1

where:

- 0 is the inlet of the compressor, station 0

- 1 is the inlet of the impeller, station 1

- p is the pressure

- ρ is the density and indicates that it is a function of pressure

- is the flow speed

- γ is the ratio of the specific heats of the fluid

Centrifugal impeller

The identifying component of a centrifugal compressor stage is the centrifugal impeller rotor. Impellers are designed in many configurations including "open" (visible blades), "covered or shrouded", "with splitters" (every other inducer removed), and "w/o splitters" (all full blades). Figures 0.1, 1.2.1, and 1.3 show three different open full inducer rotors with alternating full blades/vanes and shorter length splitter blades/vanes. Generally, the accepted mathematical nomenclature refers to the leading edge of the impeller with subscript 1. Correspondingly, the trailing edge of the impeller is referred to as subscript 2.

As working-gas/flow passes through the impeller from stations 1 to 2, the kinetic and potential energy increase. This is identical to an axial compressor with the exception that the gases can reach higher energy levels through the impeller's increasing radius. In many modern high-efficiency centrifugal compressors the gas exiting the impeller is traveling near the speed of sound.

Most modern high-efficiency impellers use "backsweep" in the blade shape.[2][3][4]

A derivation of the general Euler equations (fluid dynamics) is Euler's pump and turbine equation, which plays an important role in understanding impeller performance. This equation can be written in the form:

Equation-1.2 (see Figures 1.2.2 and 1.2.3 illustrating impeller velocity triangles)

where:

- 1 subscript 1 is the impeller leading edge (inlet), station 1

- 2 subscript 2 is the impeller trailing edge (discharge), station 2

- E is the energy added to the fluid

- g is the acceleration due to gravity

- u is the impeller's circumferential velocity, units velocity

- w is the velocity of flow relative to the impeller, units velocity

- c is the absolute velocity of flow relative to stationary, units velocity

-

Figuer1.2.2 -Inlet velocity triangles for centrifugal compressor impeller

-

Figuer1.2.3 - Exit velocity triangles for centrifugal compressor impeller

Diffuser

The next component, downstream of the impeller within a simple centrifugal compressor may the diffuser.[5][4] The diffuser converts the flow's kinetic energy (high velocity) into increased potential energy (static pressure) by gradually slowing (diffusing) the gas velocity. Diffusers can be vaneless, vaned, or an alternating combination. High-efficiency vaned diffusers are also designed over a wide range of solidities from less than 1 to over 4. Hybrid versions of vaned diffusers include wedge (see Figure 1.3), channel, and pipe diffusers. Some turbochargers have no diffuser. Generally accepted nomenclature might refer to the diffuser's lead edge as station 3 and the trailing edge as station 4.

Bernoulli's fluid dynamic principle plays an important role in understanding diffuser performance. In engineering situations assuming adiabatic flow, this equation can be written in the form:

Equation-1.3

Antropológia

Aplikované vedy

Bibliometria

Dejiny vedy

Encyklopédie

Filozofia vedy

Forenzné vedy

Humanitné vedy

Knižničná veda

Kryogenika

Kryptológia

Kulturológia

Literárna veda

Medzidisciplinárne oblasti

Metódy kvantitatívnej analýzy

Metavedy

Metodika

Text je dostupný za podmienok Creative

Commons Attribution/Share-Alike License 3.0 Unported; prípadne za ďalších

podmienok.

Podrobnejšie informácie nájdete na stránke Podmienky

použitia.

www.astronomia.sk | www.biologia.sk | www.botanika.sk | www.dejiny.sk | www.economy.sk | www.elektrotechnika.sk | www.estetika.sk | www.farmakologia.sk | www.filozofia.sk | Fyzika | www.futurologia.sk | www.genetika.sk | www.chemia.sk | www.lingvistika.sk | www.politologia.sk | www.psychologia.sk | www.sexuologia.sk | www.sociologia.sk | www.veda.sk I www.zoologia.sk